ایک فاسٹنر ایک ہارڈ ویئر ڈیوائس ہے جو میکانکی طور پر دو یا دو سے زیادہ اشیاء کو ایک ساتھ شامل کرتا ہے یا اس سے جوڑ دیتا ہے۔ عام طور پر ، فاسٹنر غیر مستقل جوڑ بنانے کے لئے استعمال ہوتے ہیں۔ یعنی جوڑے جو جوڑنے والے اجزاء کو نقصان پہنچائے بغیر ہٹا یا ختم کیا جاسکتے ہیں۔

Most of fasteners are made in accordance with the standards which can be easily

bought from market. However, some of the fasteners need to be specially made for

meeting its unique applications. In last decades, Auwell has received lots of

custom made fastener inquiries and orders. Custom made fastener has becomes one

of Auwell’s important product line.

The most common material for custom made fastener are stainless steel,

carbon steel, and alloy steel. The major grade used in stainless steel

fasteners: 200 series, 300 series, and 400 series. Titanium, aluminum, and

various alloys are also common materials of construction for metal custom made fastener.

In most of cases, the custom made fastener production started with

material hot forging followed by CNC machine, threading and surface treatment.

The special coatings or plating may be applied to metal fasteners to improve

their performance characteristics by, for example, enhancing corrosion

resistance. Common coatings/platings include zinc, chrome, and hot dip

galvanizing.

Auwell is capable in CAM programming for high efficiency and desirable

quality for our Custom made fastener. The Auwell team can design the necessary

fixtures and tools for the milling process and test gauge for Custom made

fastener mass production quality control. CMM is available for sample dimensional

inspection. PPAP documents are available upon request.

Auwell custom made fastener advantages

-رچ تجربہ

کسٹم میں 20 سال سے زیادہ کی تجربہ نے فاسٹینر کی تیاری اور تیاری کی ، خاص طور پر یورپی اور شمالی امریکہ کے بازاروں کو راغب کیا ، دنیا بھر میں جسمانی ، تکنیکی اور معیار کے معیار کی ٹھوس تفہیم کے ساتھ۔

-فاسٹ ٹرناراؤنڈ

Generally, we provide a

quotation for Custom made fastener within 3 working days. Combining the latest

manufacturing technologies and facilities, Auwell can provide fast prototypes

in just 2 weeks for simple projects.

-جامع حل پرووائڈر

Auwell provides

comprehensive services for Custom made fastener starting from designing,

through prototyping, tooling/fixture development, sampling, mass production,

and logistic and post-sale support.

-سخت QC پالیسیاں

The most rigorous quality

policy for our Custom made fastener starts from material control and is

followed through to final pre-shipment inspection. Material certificates

include the mill certificate, 3rd party chemical components, and mechanical

property reports, as well as RoHS and REACH reports upon request. Other reports

include dimensional reports, surface treatment thickness, and salt fog test

reports, etc. We structure our processes, creating Flow Charts and Control

Plans before production, making sure all QC processes are in accordance with

ISO9001-2015 requirements and drawing specifications.

-لچکدار ادائیگی کی مدت

بڑے پیمانے پر پیداوار کے لئے ، ویلفر لچکدار ادائیگی کی شرائط ، مناسب ساکھ کی شرائط دی جائیں گی ، مؤکل ادائیگی کرتا ہے جب وہ موصول ہونے والی مصنوعات سے خوش ہوتے ہیں۔ طویل مدتی منصوبوں کے ل For ، ہم تیزی سے ترسیل کی ضروریات کے لئے کال آف انوینٹری خدمات پیش کرتے ہیں۔

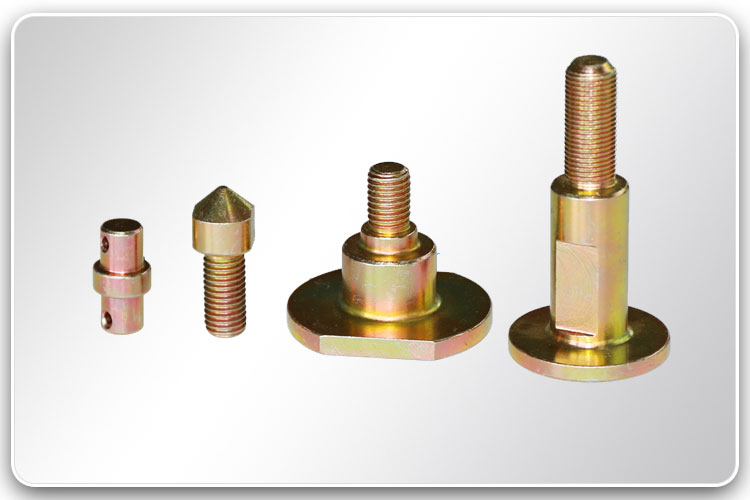

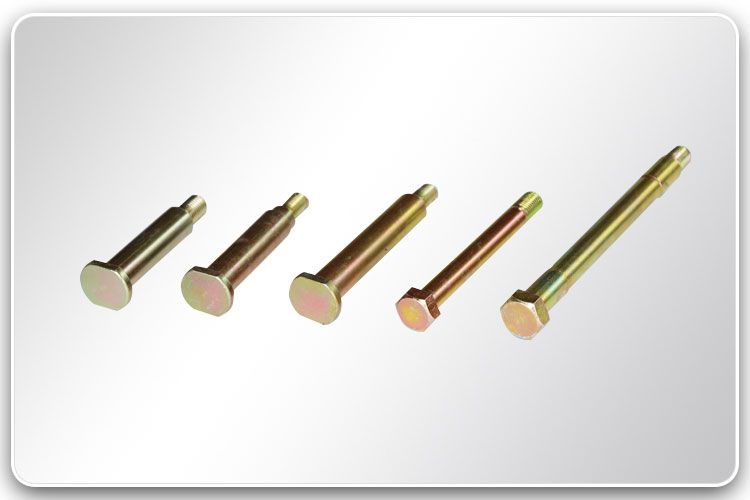

The following catalogues of Custom made fastener are the ones that Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purposes only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик